How Right Industrial Floor Installation Keeps Your Production Line Running

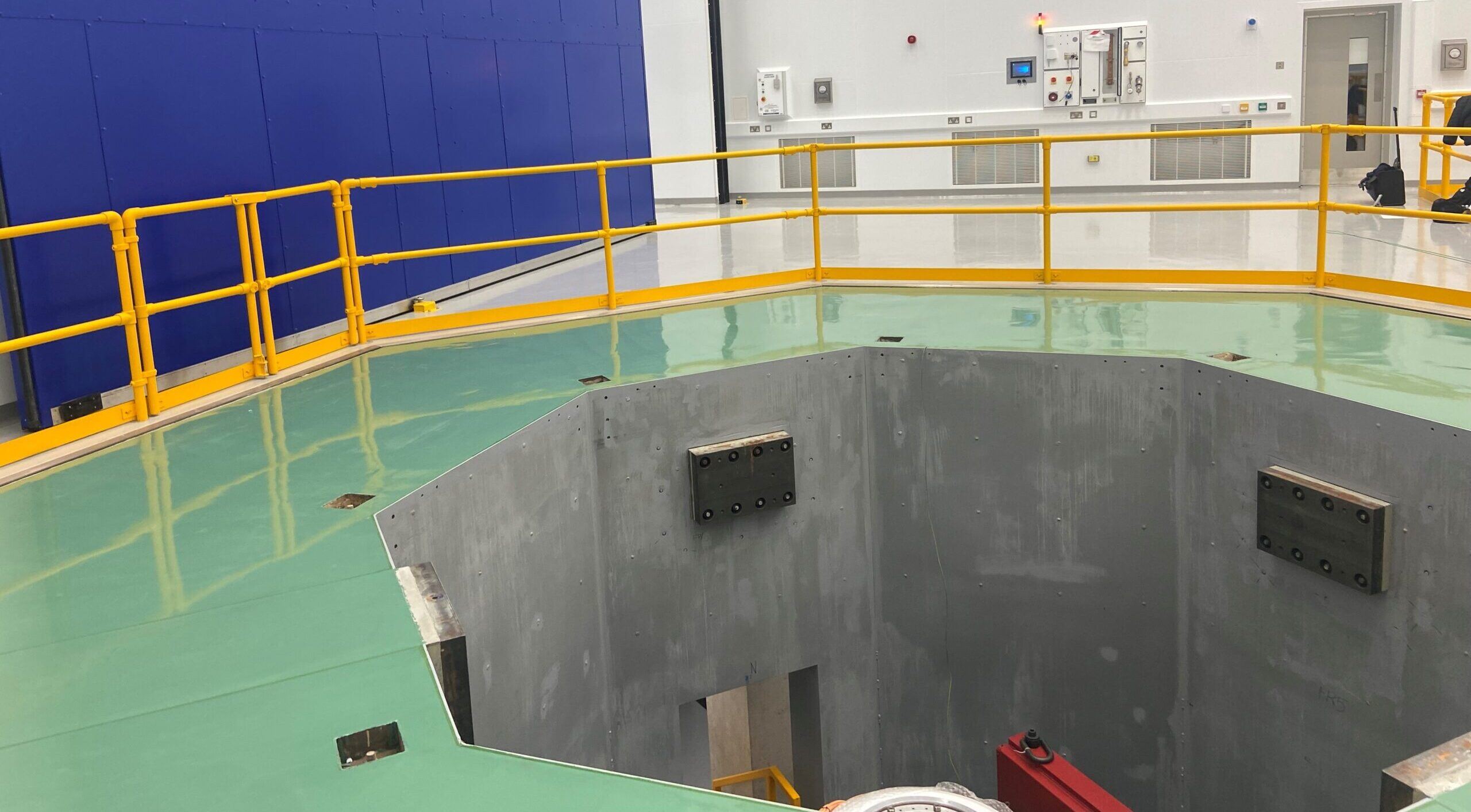

The floor in any industrial setting is not just a surface but a critical piece of infrastructure that directly impacts safety, hygiene and, perhaps most importantly, operational continuity. For contractors and facilities managers, choosing the correct industrial floor installation is a strategic decision. A poorly chosen or badly installed floor is a liability, leading to costly downtime for repairs, increased accident risks and the perils of non-compliance. Conversely, the right industrial resin flooring system ensures that the production line runs efficiently and safely.

Minimising Downtime With Expert Industrial Floor Installation

Downtime is the enemy of profit, and scheduling a new industrial floor installation requires careful planning to minimise disruption to the production cycle. Expert contractors understand that installation speed and curing time are often the biggest variables that can halt operations.

Choosing rapid curing industrial resin flooring systems, such as specific polyurethane or fast-setting epoxy resins, allows for quicker return-to-service. While traditional concrete may take days or weeks to cure sufficiently, modern resin floors can often be fully operational in as little as 24 to 48 hours. A professional installer works closely with the facility to segment the work, allowing production to continue in phased areas. This approach, coupled with materials that achieve maximum strength quickly, ensures the facility is back up and running with minimal interruption.

Safety And Preventing Accidents With Slip-Resistant Resin Floors

Employee safety is paramount, and the flooring surface is the primary defence against slips, trips and falls (which are the leading cause of workplace accidents). Specifying slip-resistant resin floors is a non-negotiable requirement for areas exposed to water, oils, chemicals or frequent washdowns.

A quality industrial resin flooring system achieves slip resistance through the incorporation of aggregates (like quartz or aluminium oxide) embedded within the resin layer. The degree of texture, measured by the pendulum test value (PTV), must be carefully matched to the environment. For instance, a wet food processing area will require a much higher PTV than a dry warehouse.

-

Wet Zones: Require a coarser profile to maintain grip even when saturated.

-

Dry Zones: Can use a smoother texture for easier cleaning while still providing adequate friction.

This customisation ensures that the floor performs optimally for safety without compromising the ability to clean and sterilise the area efficiently.

Durability And Chemical Resistance In Extreme Environments

In sectors like aerospace, automotive and, particularly, the chemical industry, the floor must withstand extreme mechanical stress, thermal cycling and continuous chemical exposure without degradation. The durability of the chosen system directly correlates to its lifespan and the avoidance of expensive repairs.

Industrial resin flooring materials like high-build epoxy, polyurethane screeds and methyl methacrylate (MMA) offer varying degrees of resilience. For areas with heavy forklift traffic, impact-resistant polyurethane screeds are often superior. When considering chemical industry flooring installation, resistance to concentrated acids, solvents and fuels is critical.

Epoxy systems are generally highly chemical-resistant, but specific chemical industry flooring installation may require a specialised epoxy to protect the substrate from aggressive corrosive compounds. By specifying the correct chemical formulation, the floor acts as an impervious barrier, preventing toxic substances from penetrating the concrete and causing structural damage or contamination.

Ensuring Seamless Hygiene And Compliance

For industries governed by strict hygiene regulations, such as food and beverage processing or pharmaceuticals, the flooring must support decontamination efforts and be completely seamless to prevent bacterial harbourage.

A key feature of a modern hygienic flooring system is its seamless application. Unlike tiles or sectional flooring, industrial resin flooring is poured and cured in place, eliminating joints, seams and grout lines where microbes thrive. The installation process should always include coving (a smooth, upward curve where the floor meets the wall). This detail removes the sharp 90-degree corner, making washdowns easier and ensuring that no debris or bacteria can collect. Choosing a system that is non-porous and easy to steam-clean ensures regulatory compliance and helps maintain the highest standards of sanitation, keeping the production line running without risk of product contamination.

Consult The Experts On Industrial Resin Flooring Selection

A successful industrial floor installation is a strategic investment in operational efficiency, safety and compliance. By focusing on rapid-curing materials to minimise downtime, specifying slip-resistant resin floors for safety, choosing chemically resilient industrial resin flooring for challenging environments and ensuring a seamless hygienic flooring system for compliance, contractors can deliver a foundational asset that protects both the business and its personnel. The right floor system keeps the production line moving reliably, day after day.

To find out more about how to choose the right kind of industrial flooring, get in touch with a member of our expert team here at Central Flooring Services. Book your free, no-obligation site survey today. We provide tailored recommendations to meet specific regulatory requirements and ensure maximum operational efficiency for your business.

Image Source: Canva

You May Also Like

These Related Stories

Why Chemical Resistant Flooring Is Essential for Food Industries

Central Flooring installs anti-static flooring system for Mace at Harwell Innovation Campus