Why Chemical Resistant Flooring Is Essential for Food Industries

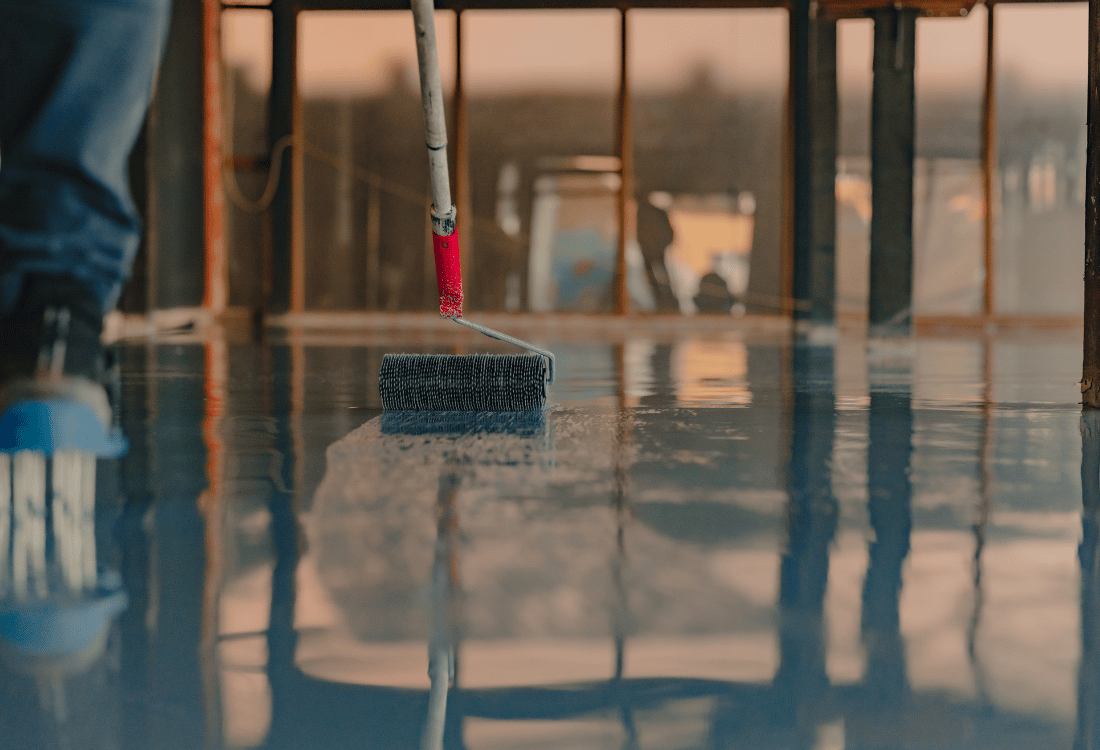

Perhaps more than any other industry, hygiene, health and safety are fundamental to food processing facilities. But one aspect of industrial food production safety that can be overlooked is the floor. With constant exposure to harsh cleaning chemicals, extremes of temperature and often heavy traffic, the floor in these types of facilities needs to be extremely resilient, reliable and easy to clean. Which is why so many facilities are choosing to install chemical resistant flooring.

From protection against corrosion to ensuring compliance with strict food safety regulations, chemical resistant flooring is a key ingredient in the health and safety system of any facility. Below we will explore more reasons why food safe flooring is essential, including the main types available, the main benefits and how to maintain it for maximum performance and longevity.

Understanding Chemical Resistant Flooring

Chemical resistant flooring refers to floor systems designed to withstand exposure to corrosive chemicals, such as acids, alkalines, oils and solvents. This is particularly relevant to the food industry because cleaning and sanitising agents are used frequently, often several times a day. In addition, substances such as animal fats, dairy products and fruit acids can cause damage to floor surfaces over time. This includes cracks and erosion which can create pockets where bacteria can gather. Chemical resistant flooring prevents this from occurring by creating a seamless barrier against damage.

Types Of Chemical-Resistant Flooring

There are several main types of chemical-resistant flooring commonly used. These include

-

Epoxy resin flooring: This provides a high gloss and high resistance finish, which is ideal for food preparation zones.

-

Polyurethane flooring: PU flooring, as it is known, is well known for its resilience under thermal shock. They are also very resistant to organic acids, which is useful in food production.

-

Methyl methacrylate flooring: MMA flooring systems can cure quickly and can be installed in cold environments.

Benefits Of Chemical-Resistant Flooring

The major benefits of chemical-resistant flooring include enhanced sanitation and hygiene, thanks to a seamless surface that prevents the absorption of liquids and bacteria. This helps to prevent contamination in areas where spills and splashes are common. This type of flooring also offers impressive longevity and durability, being able to withstand harsh environments and requiring fewer repairs and less maintenance over time. They also meet regulatory compliance, helping you to avoid fines and penalties.

Maintenance Tips For Food Safe Flooring

Chemical resistant flooring is built to last, but will require some help to perform at its best. This includes routine cleaning using non-abrasive and pH-balanced products that will not compromise surfaces. Prompt clean-ups are also important when spills do happen, as this limits exposure to harmful chemicals. Floors should be regularly inspected, and professional recoating should be carried out on the more exposed areas to ensure resistance and shine.

You can find out more about chemical resistant and food-safe flooring by getting in touch with our team here at Central Flooring Services. We are more than happy to talk through your flooring needs and concerns and can recommend the most suitable flooring solutions for your facility.

Image Source: Canva

You May Also Like

These Related Stories

How To Improve Reduce Slip Hazards With Industrial Resin Flooring

What Is The Best Chemical Resistant Flooring For Laboratory?