ESD Flooring Specifications: Top 5 Features for Safety and Efficiency

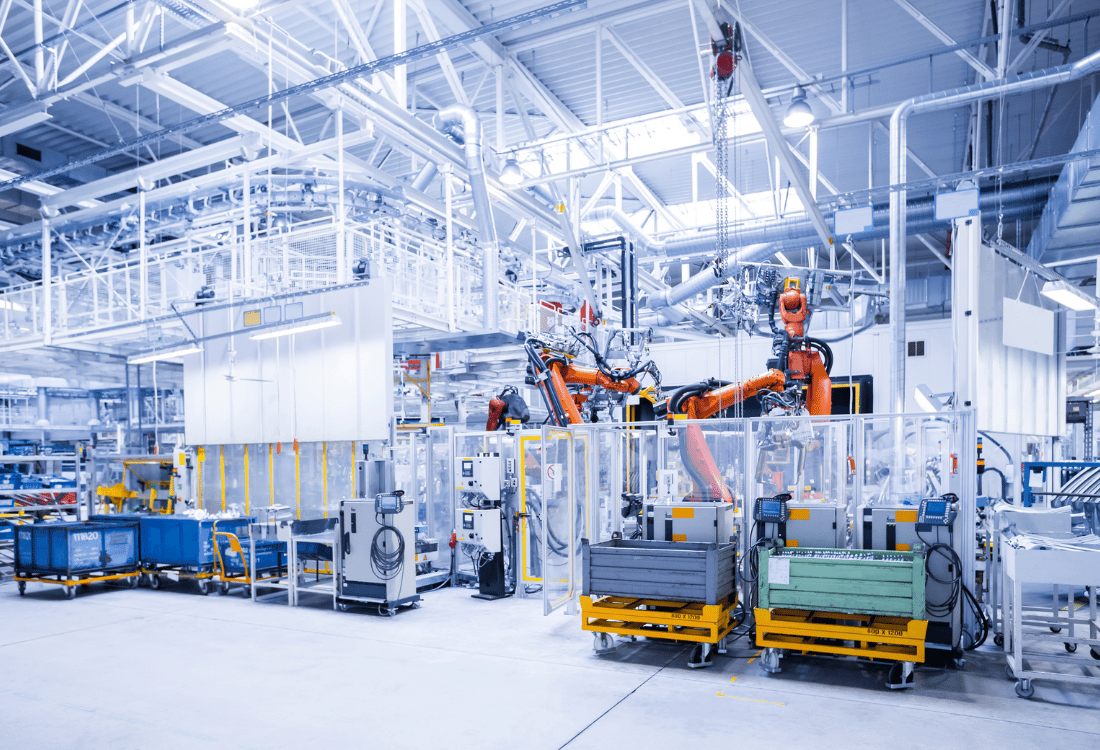

Electrostatic discharge (ESD) can pose serious risks to both people and sensitive equipment. Whether you operate in electronics manufacturing, pharmaceuticals, aerospace or data centres. ESD flooring plays a critical role in maintaining safety and operational continuity. Choosing the right system begins with understanding key ESD flooring specifications that define performance and reliability, as well as compliance.

Let’s explore the top five features you should consider when specifying ESD flooring to maximise both safety and efficiency in your facility.

1. Electrical Resistance Ratings

The most essential component of any ESD flooring specification is its electrical resistance range. The flooring must effectively dissipate static electricity while maintaining safe resistance levels to avoid hazards.

There are three general categories:

Conductive flooring: 25,000 ohms to 1 million ohms

Dissipative flooring: 1 million ohms to 1 billion ohms

The ideal choice depends on your application. For instance, electronics manufacturing often requires conductive flooring for faster static discharge, while dissipative flooring may be suitable for areas with human interaction due to safety considerations. Always verify the ESD flooring’s resistance values are compliant with ANSI/ESD S20.20 or IEC 61340 standards.

2. Compliance With Industry Standards

Not all ESD floors are created equal. Ensure the product meets recognised ESD flooring specifications, including:

-

ANSI/ESD S7.1 (measuring resistance from floor to ground)

-

ANSI/ESD STM97.1 & STM97.2 (resistance and body voltage tests with personnel)

-

IEC 61340-5-1 (international ESD protection standard)

Compliance with these standards ensures that your flooring system will function properly in real-world conditions, not just in a lab setting. It also helps avoid costly compliance issues during audits or certifications.

3. Durability And Chemical Resistance

Since many ESD floors are installed in demanding industrial or commercial environments, the system must offer high durability and chemical resistance. Look for ESD flooring options that can withstand:

-

Heavy foot and cart traffic

-

Abrasion and impact

-

Exposure to oils, solvents, and cleaning agents

Resin based ESD floors, such as epoxy or polyurethane coatings, offer excellent wear resistance and are ideal for areas that require both static control and durability. Choosing a resilient flooring system reduces the risk of failure, lowers maintenance costs and extends the floor's service life.

4. Ease And Quality Of ESD Flooring Installation

No matter how high quality the product is, ESD flooring installation directly affects performance. Improper installation can result in gaps in conductivity, inconsistent resistance levels and even premature floor failure.

Partner with experienced installers who:

-

Understand grounding requirements

-

Properly prepare the substrate

-

Use compatible adhesives and primers

-

Test the system post-installation for compliance

Post-installation verification should include point-to-point and point-to-ground resistance testing. A comprehensive installation also ensures long-term reliability and minimises the risk of ESD events.

5. Maintenance Requirements And Lifespan

When selecting a flooring system, consider how easily it can be maintained without compromising ESD performance. Many ESD floors require specific cleaning agents to preserve conductivity. Choose a system with low maintenance demands and clearly outlined care guidelines.

Also, assess the system’s expected lifespan. High-quality ESD flooring can last 10–20 years when properly installed and maintained. Opting for a long-lasting, low-maintenance solution reduces downtime and operational costs in the long run.

Whether you're upgrading an electronics facility or building a new cleanroom, always consult professionals with a proven track record in ESD flooring installation like our team, here at Central Flooring. A well-informed decision today will pay off in long-term safety and operational reliability.

You May Also Like

These Related Stories