Where would you use electrostatic dissipative (ESD) resin floors

Electrostatic dissipative (ESD) resin floors are specifically designed to control static electricity in environments where it can pose risks such as in electronics manufacturing, healthcare facilities, laboratories and clean rooms – and places with sensitive equipment such as automotive, aeronautical, medical and oil and chemical processing.

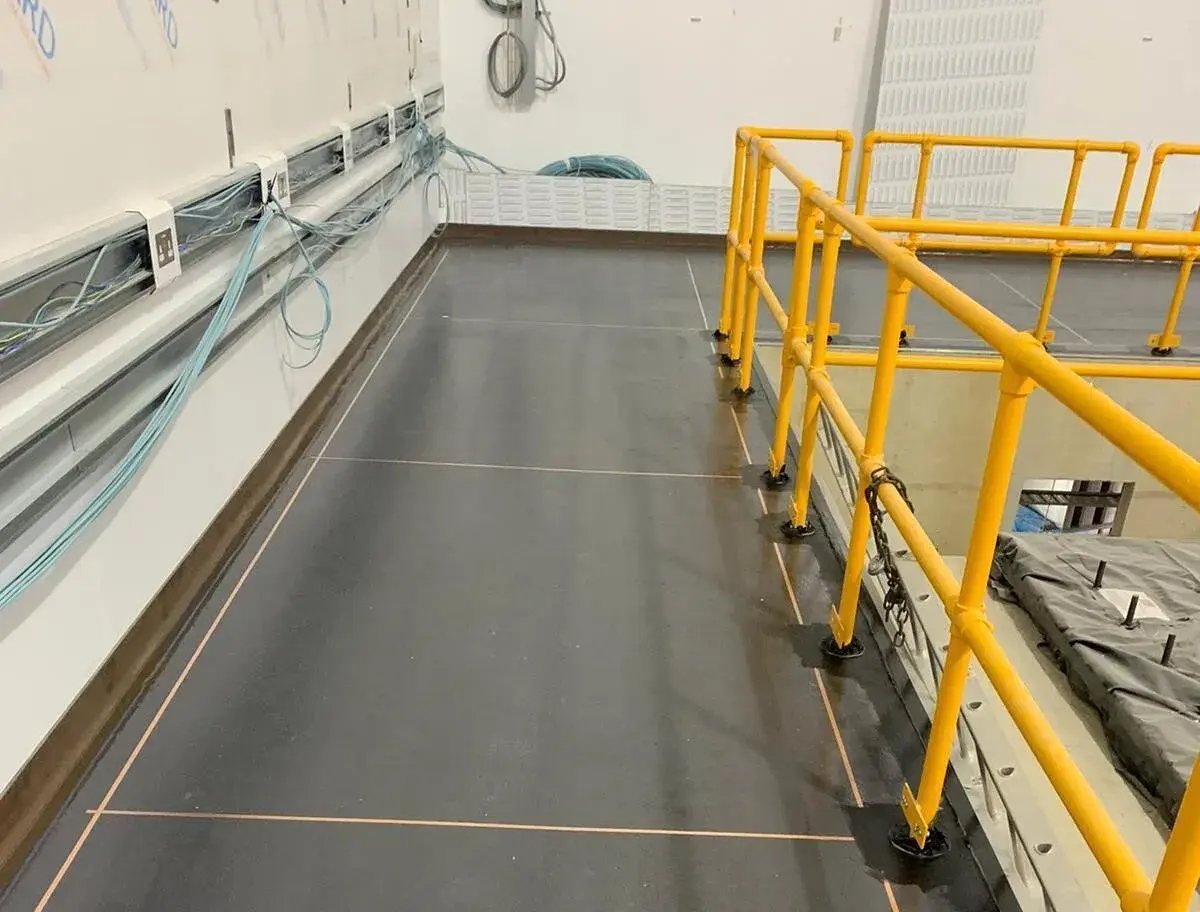

One of the largest ESD flooring systems we’ve installed is for Mace at the Harwell Science and Innovation Campus in Oxfordshire. Using the Flowcrete system from start to finish, this SR1 Level floorspace, measures almost 3500 square meters. This is what they said about our workmanship Mace | Central Flooring Services

When we install Electrostatic Dissipative resin floors, we also arrange for anti-static properties testing to be carried out in line with the manufacturers guidelines and provide you with a test certification.

The numerous benefits to businesses

Static Control

Electro dissipative floors prevent static discharge that could potentially damage sensitive electronic components or equipment and enhance safety by minimising the risk of static shocks to people working with sensitive equipment, reducing discomfort and potential safety hazards.

Protection of Sensitive Environments

Spaces like clean rooms, laboratories, or manufacturing areas where static electricity can interfere with processes or damage sensitive materials are classed as critical environments. Take the electronics industry, an ESD flooring system is particularly beneficial here, where even small static discharges can harm delicate electronic components.

Durability and Functionality

ESD resin floors offer a seamless, smooth surface that’s easy to clean and maintain. Many ESD resin flooring systems are resistant to chemicals, oils, and other substances, extending their lifespan and maintaining functionality.

Compliance and Standards

Designed to meet specific industry standards, ESD floors ensure compliance with regulations set for static control in different environments. These specialist floors come with certifications proving their effectiveness in controlling static electricity.

Customisation and Aesthetics

Despite their functional benefits, ESD resin floors offer a variety of design options, colours, and finishes, allowing customisation to match the artistic requirements of different spaces. Some floors can be finished to provide a reflective surface, enhancing light reflection and improving overall visibility.

Long-Term Cost Savings

ESD resin floors typically want minimal maintenance, reducing long-term operational costs. Their robust nature and resistance to wear and tear contribute to longer lifespans, reducing the need for frequent replacements or repairs.

Environmental Considerations

Some ESD resin flooring systems are eco-friendly, using materials that are low in volatile organic compounds (VOCs), contributing to healthier indoor air quality. Certain flooring materials used in ESD systems are recyclable, promoting sustainability and reducing environmental impact.

For more information on Electro Dissipative Flooring Systems or to see our installations back catalogue, please contact the team on 0116 502 2260 or email sales@centralfloorse.wpengine.com

What our clients say

Read what Mace said about their ESD flooring installation at Harwell Campus.

Whether you're interested in residential or commercial flooring solutions, we are committed to providing you with the best options tailored to your needs. Your satisfaction is our priority, and we look forward to assisting you!

We’re here to help! Please fill out the enquiry form and our friendly team will get back to you promptly.

Make an enquiry

Products we use

Stay up to date with the latest news

Is Resin Flooring Safe For The Food Industry?

5 Surprising Benefits Of Hygienic Flooring Systems

.webp?width=150&height=100&name=NQA_ISO14001_CMYK_UKAS-1%20(1).webp)